-

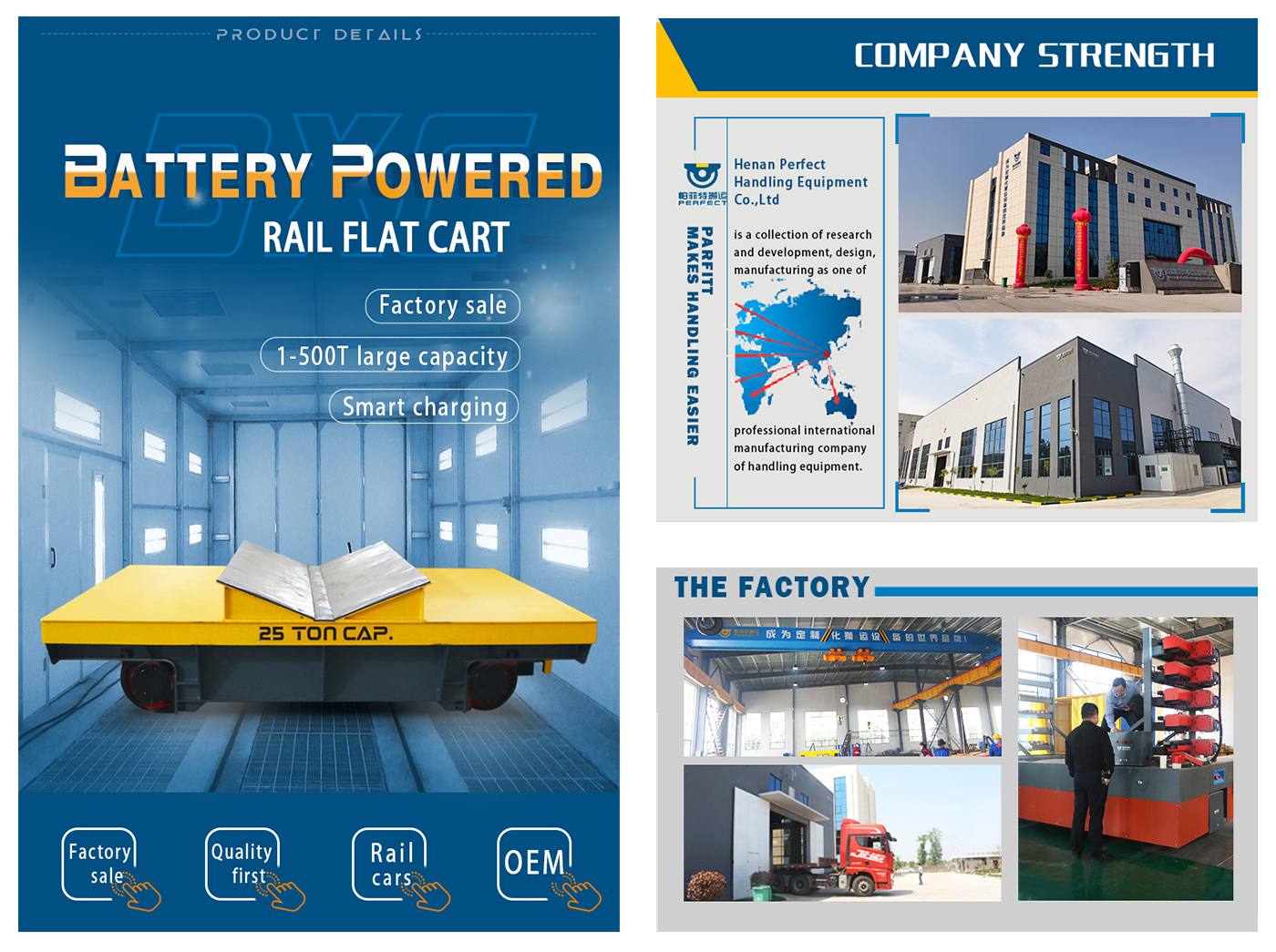

INDUSTRAIL TRAILERAckermann Steering TrailerDouble Directions Tow TrailerGeneral TrailerHeavy Duty TrailerRAIL TRANSFER TROLLEYBattery Powered Transfer TrolleyCable Powered Transfer TrolleyRail Powered Transfer TrolleyTRANSFER CART ON WHEELSAGVDifferential steering Transfer CartHydraulic Steering Trackless VehicleOmnidirectional Mobile Trackless Vehicle

-

-